Production for Future is a non-profit project in Gothenburg, Sweden, with the goal of inspiring and educating young people about modern technology. Together with upper secondary school students and university students, the project builds small “smart factories.” These factories are then used in workshops for students of all ages.

To ensure the factories remain up to date and relevant in today’s industry, the project regularly hosts thesis projects. Over the years, digital twins have played an important role in the development. Below are three examples of how they have been used.

3D Scanning – Supporting Relocation Decisions

When the project had to move to a new location, important questions arose:

• Will the factories fit in the new space?

• Where should they be placed?

• Where do we need electricity and infrastructure?

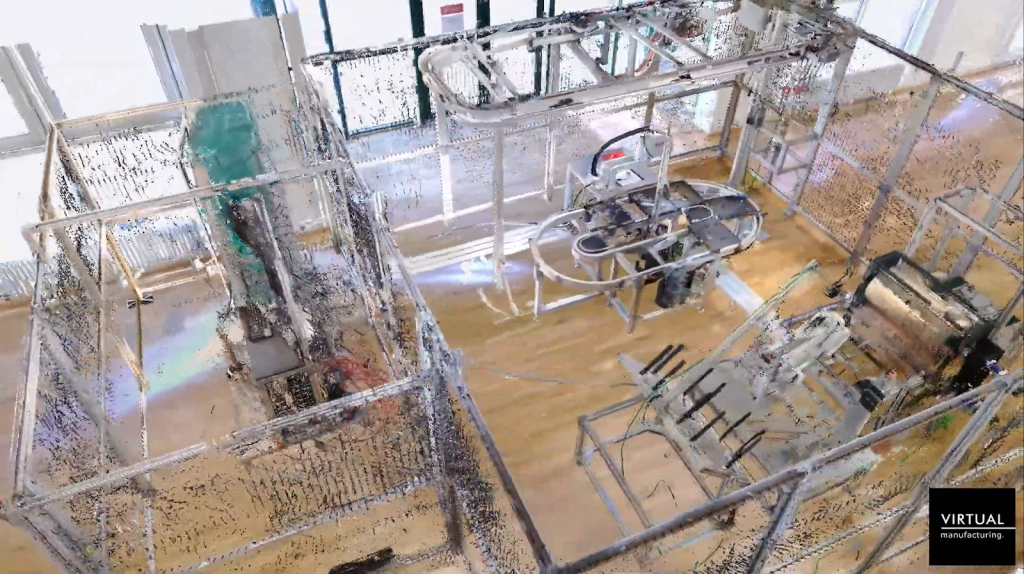

This was especially relevant for one of the larger factories, the VR-Goggle Factory, seen in the pictures below.

The solution was to create a digital twin using 3D scanning, also called point cloud scanning. By using a 3D camera to scan the existing factory, it was possible to see that the factory would fit and also where to place it so it could be accessed where needed. A problem with the new location was a pillar in the middle of the room, something that could have become a big issue. Instead, it was easy to quickly try new placements using the digital twin without having to move anything physical.

Pre-Physical Digital Twin / Virtual Commissioning

Another application of a digital twin in Production for Future was building a pre-physical factory, meaning that a virtual model is built before the physical factory. Creating a pre-physical digital twin to test the factory is called virtual commissioning. It is primarily done to save time and cost, as it is possible to ensure that the layout works and that all parts fit together as intended before ordering any materials.

Despite creating a digital twin beforehand, the project faced problems while building the factory. It turned out that the legs for the lens transporter in the physical factory were attached approximately 0.5 m inwards. What was learnt in the project while creating a pre-physical digital twin is that it is very important to have all data when creating a digital twin, even if it seems unimportant at the moment. Luckily the leg placement didn’t create any problems for the overall layout. The image below is a screenshot of the pre-physical digital twin of the VR-Goggle Factory. It was created in RobotStudio – ABB’s virtual environment, which allows users to insert digital twins of their robots from a database.

Virtual Reality – Ergonomics and User Experience

Virtual Reality has also been used together with pre-physical digital twins to evaluate ergonomics, work environment, and usability.For the development of a new installation, the Assembly Factory, a digital twin was created. This digital twin was also made in RobotStudio, as it uses ABB’s collaborative robot YuMi.

Using a HTC Vive VR headset, users evaluated workstation heights, distances, and overall design to ensure that the environment would be comfortable, safe, and practical for future operators. This approach supported both design validation and virtual commissioning, contributing to a smoother and more efficient real-world implementation.